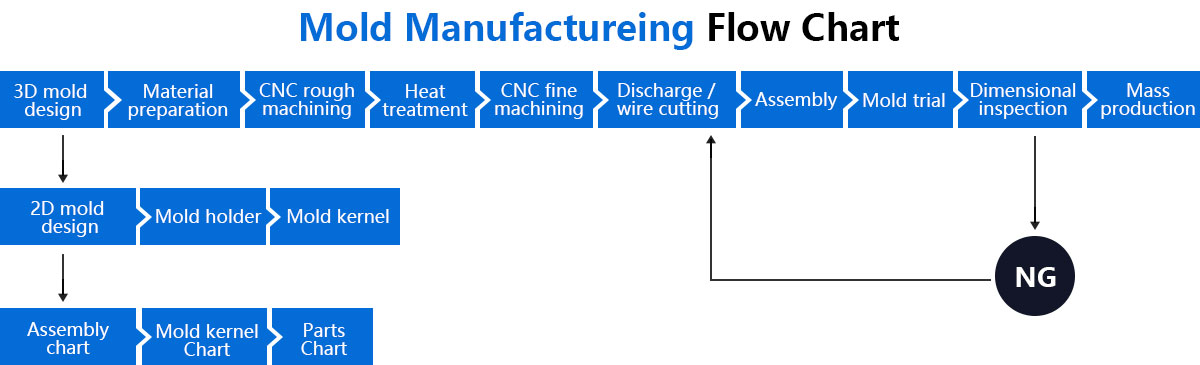

Mold department

Tech-Casting has a strong team of professional designers who cooperate with computer program aided design to make mold design more perfect.

It is urgent to improve the design quality. We specially allocate R&D funds in the annual budget to improve staff skills, and constantly update software and hardware equipment, so as to improve mold precision, increase competitiveness, and better meet the rapid needs of customers to achieve high-quality manufacturing standards.

Mold technology:

1. Verticality of die parts shall be within 0.002 at 50MM;

2. The wire cutting and processing process adopts immersion processing, and the thimble and hole shall be matched loosely and smoothly, with the precision of+0/-0.005 and+0/+0.003MM;

3. SKH-9 is used as the die steel material. The heat treatment reaches 60~62 degrees (generally SKD61 or 8407, 50~54 degrees);

4. The discharge standard is based on the Sadik comparison card, which is generally 5.2 or semi mirror. (according to customer requirements);

5. Mold design can shape holes, reducing the post processing process;

6. The service life of the mold is 1 million.

7. The mold design adopts the latest technology to minimize the mold line of the product and make the product look beautiful.

8. For electrode processing, the electrode adopts the company's unique professional fixture processing technology, and the CNC to the spark machine reduces the clamping error to achieve more accuracy.